Does Extraglaze need Listed Building Consent?

We commonly install Extraglaze in listed buildings, and in the UNESCO World Heritage Site of the Ironbridge Gorge (very near and dear to us) - all without formality.

We can honestly report that our customers have never told us they needed to get Listed Building Consent nor planning approval for an Extraglaze installation in any listed building. However, we always recommend our customers speak to their local authority and often a phone call is all it takes, sometimes followed by a visit, but no paperwork or fees is likely. It is certainly wise, indeed essential that you get a “good-to-go” message, verbal or written, for your own peace of mind, and importantly not from us, but directly from the proper authority. We do not offer to do this important task for you as a go-between. But we will help you (read on please).

NOTE: for many Listed Buildings the requirement for consent applies to specific parts of the building only. You should check. For example, while your entrance door or chimneys may be classed “listed” the rest of your house might not!

Some local authorities are, unfortunately, more difficult to deal with than others. While instances are increasingly rare Listed Building Consent may be considered 'necessary' in the first instance, when you are given a blanket "standard answer" for any work in a listed building. The good news comes when you press in and conclude by verbal/simple agreement that it is not necessary for your secondary glazing, usually after providing additional product information (such as a link to our web site and a Free Sample*), answering some simple questions and maybe even a visit to the property from a member of the local conservation team. The key issues they want addressed are:

- can the secondary glazing be removed at a later date so that the windows are returned to their existing condition? You can say YES for Extraglaze**

- will the secondary glazing be seen from outside? Our answer is NO (except perhaps to the trained eye, probably nothing more than an extra reflection from the inside panel).

* we will send you a Free Sample or send it direct to the Conservation Officer you specify (after agreeing he/she will receive it). They can view our web site at any time of course. And they are very welcome to talk to us.

** Should you need to remove Extraglaze permanently (for example to do some serious renovation work) then it is easily removed. When removing the frame-side magnets they will take paint off your window frames, so you just need to repaint them afterwards. Repainting is of course part of ongoing maintenance (you can even call it healthy), not a physical change to your property. If you wish to install the panels again later then you will simply need some new frame-side magnets, available from our Accessories shop.

Extraglaze performance: thermal and sound insulation

Extraglaze has been scientifically proven to reduce heat loss and sound transmission. A summary of the tests undertaken and the impressive results is described here.

Please remember to read the testimonials of our many customers, collected independently by Feefo.

Does Extraglaze stop condensation?

Extraglaze can be an excellent long term solution, reducing and more often than not eliminating condensation. If your panels are fitted on a cold winter's day then for some days afterwards it is common to still experience condensation on the original window glass, because the installer breathes all over the window while working, and his/her breath is caught in the gap as soon as the panel is applied. However, on a warmer, dry day the panel can be removed to allow (or waft) dry fresh air to replace the damp air, or indeed so you can wipe the glass dry. Condensation does not usually return (unless there is a fresh source of dampness within the window itself e.g. direct rain, leaks through putty and leaded glass, a dripping gutter above causing damp wood or bricks). Instances of mould are reduced dramatically, usually eliminated, as the cavity dries out and stays dry. Consequently the life of the paintwork on an intricate window frame is greatly extended, and stays looking fresh.

If the window has suffered condensation prior to the installation then it is likely that water has puddled on the frames and soaked into the wood below the paint surface. As soon as the Extraglaze is installed then this creates a little greenhouse on your window, consequently during the day the air in the gap gets quite warm. Soon the wood will "perspire" and start drying out. This is very good news for your window frame, but you will find condensation inside the gap on the glass in the mornings*. The solution is to remove the panel and wipe off the condensation (this works best on a warm dry day, but it is not essential to wait), or to allow this to evaporate (this may happen later in the day) then, with the panel removed, waft dry, fresh air into the gap. You may have to do this several days in a row. At some time the frame will be dry, the air in the gap will no longer be humid and this will stop happening.

* if on a cold winter's night you cover your secondary glazing with shutters or thermal lined curtains then the secondary glazing will be insulated from the warmth in the room. It will therefore be chilled by the outside window. It will become the coldest surface in the room. When you open the shutters/curtains then you will see condensation there. But as soon as the secondary glazing gets a chance to warm up it will dry itself, assuming the room is heated, and especially if there is a radiator beneath it. In severe cases, such as wet or laundry rooms, or homes where humidifiers have already proven essential, then you will need to wipe the condensation off the panel on cold mornings. This will prove very easy in comparison to wiping your window, and happily the panel is made from non porous materials so it is ideal for coping with condensation.

You may read that secondary glazing does not solve condensation. This is commonly known for secondary glazing made of glass. Extraglaze however is superior to other types of secondary glazing because the acrylic can maintain a comparatively warm surface, rarely cold to the touch. A chill does not pass through the acrylic nearly as well as it can through glass (glass will transmit heat about 5 times faster. Please note there are some incorrect statements on the internet that suggest it is the other way around!). So the inner pane of your window, i.e. the Extraglaze, is not prone to collect condensation.

IMPORTANT NOTES

Condensation is a symptom of insufficient ventilation i.e. a humid indoor atmosphere. Extraglaze does not cure this. Humidity is commonly a result of laundry being dried indoors, steam from showers & baths, kettles, poorly vented tumble dryers, cooking pots and a busy house full of people. The recent trend towards exercising indoors with gym equipment also increases humidity indoors. If you have had any concreting or plastering completed in your home then these can add a considerable amount of moisture to the indoor atmosphere, therefore you can expect severe condensation over several days following. When walls are being painted you will also get more condensation than usual.

Condensation may start to settle elsewhere i.e. humidity may condense on another cold spot in your property. Condensation is most common upstairs, because humidity rises up with hot air. If you still experience condensation after Extraglaze has been fitted then do check it for gaps i.e. where the magnets may not be mating correctly. This suggests incorrect fitting. If there are no obvious gaps then this is a warning sign that you have an abnormally humid room (therefore poorly ventilated or entirely unventilated) and action is required to reduce this. This would be very likely in a shower room or where you hang laundry. Poor ventilation is very likely harmful to your health and the fabric of your building.

We strongly recommend you read more on this topic in our Help & Guides section: How to stop condensation?

Can Extraglaze panels be fitted to a moving part of my window?

This should never be necessary, and in fact the simple answer is No, for three important reasons: 1) you will achieve very little gap between the existing and new secondary glazing, which will prove very ineffective 2) you will not likely seal any gaps, therefore your windows may continue to be draughty and 3) the panels may stop you being able to open some windows, or the additional weight of the panel may, sooner or later, prove detrimental to the window.

What depth of air gap is best on my windows?

For thermal efficiency a 85-100mm air gap (or cavity) is ideal, but on many windows this is not practical (and unheard of on domestic double glazed windows) because of the window frame design. In practice any gap over 25mm is still a good one, and even 20mm is not pointless, but you will get a far superior installation at larger gaps than these. So please avoid less than 25mm (if you can). Also more than 100mm is not nearly so effective: while deep air gaps can still be very satisfying (far better than no gap at all), the large cavity allows air to circulate and so heat is transferred from outside to inside.

For sound insulation a gap of 30mm is moderately effective (to the human ear at least!), increasing in effectiveness as the gap gets larger. In our tests at the Building Research Establishment the test equipment suggested a good level at 125mm, then on larger gaps the additional benefit, while helpful, quickly tailed off. If you have a window sill to think of, and don't want it all taken up by the secondary glazing then we would suggest you aim for 125mm, not more. Please do note that larger gaps compromise thermal efficiency (see earlier in this FAQ).

Will Extraglaze work behind my shutters?

Yes. If you have hinged & folding shutters, whether authentic and built into the walls, or modern louvre shutters, then magnetic secondary glazing is commonly the only option. The glazing panels are less than 9mm thick, which means they can usually fit directly behind the shutters. Where the shutters close right up tight to the window frames then it is possible to add new surfaces that are recessed within the glazing aperture. This is a method we only advise for the more competent DIY installer, or better still for one of our approved fitters, because accuracy and out-of-square can become a major obstacle, and expensive to put right if it goes wrong. If you have a bay window then this is particularly difficult for the first-time installer to get right.

Can I order coloured or frosted panels?

This question refers to the panel material i.e. not to the panel edges by the perimeter.

Tinted and coloured panels will absorb energy and therefore suffer thermal expansion problems, so we will only ever supply clear (or frosted) panels.

Frosted panels offering some privacy are available for an additional fee – please enquire.

Can you match the paint colour on my windows?

Yes. There are two methods: using paint, or using a coloured vinyl. This FAQ answer will discuss the paint option. The next FAQ answer (below) will discuss the vinyl option.

If you require your Extraglaze panels in exactly the same colour as your window frames then it's possible to use the same paint on our panels, whether we do the painting for you, or you do it yourself. When we do it then it can prove expensive, and adds several days to our processing time depending how many painted panels you order.

Please note however, most of our customers settle very happily for one of our standard colours. This is quite explainable. During the daytime, when you look at your window, you are more likely to be looking out through it, not at it. During the evening, when it is dark outside, you probably have curtains or shutters hiding it.

Nevertheless, there are certainly times when you will look more closely and admire your window frames. Consequently you will want your Extraglaze panels to be exactly the same colour. We discuss this potential problem directly with our customers every week of the year! However, easily 90% of the time they conclude that a standard colour will work just fine. So far so good, because we've never heard a customer regret that decision. Please read on to learn why.

Please consider, when you look at your window frames in the daytime...

- the frames are very likely to be in shadow, much darker than the bright daylight coming through the glass. Therefore your eyes are exposed correctly for looking outside, not inside.

- your frames may comprise a myriad of surfaces and mouldings. Despite being exactly the same paint colour every surface will be a different shade, because of how the light lands on each, and because some will reflect some of the colours around about, for example the colour of your curtains or the greenery outside. The Extraglaze panels will simply add one more of these, and their colour is easily lost amongst the many shades of your window frame.

Therefore we nearly always recommend one of our standard colours, rather than the expense of painted edges.

In the dark part of the evening, if you do not regularly draw curtains (etc) across your windows, then things might be different. Will you look at your windows a little or a lot? It will largely depend on how brightly your room is lit, how close you find yourself to them, or rather if they are in front of you or behind, for example when you are sat down. You might conclude either way, that a colour match really is important, or indeed not important.

If you are in doubt then please place one of our free samples against your window, stand back and leave it there for a while, then come back to it at different times of day.

Please also see our other FAQs, for example:

Can I order panels with bespoke coloured edges?

Regardless if your project will be DIY or Fitted by Us you can ask us to make panels using a bespoke colour, with either:

- exactly the same paint used on your window frames (after reading more here please see the FAQ answer immediately above)

- a vinyl not currently offered in our standard range.

The total price will include the price of the panels (as if standard), plus...

… for painted panels:

- a supplement per panel for those that we paint

- the cost of a tin of paint, perhaps less if one or more sample pots look to be sufficient

… for a non standard vinyl:

- a fixed price to bring the new vinyl into stock

- please contact us ASAP to discuss your order, so we can make preparations ahead of your position in the queue (because ordering a new vinyl may take several weeks).

Important:

i) we may organise enough of the new vinyl for your first order only. If you intend buying more panels later also requiring this vinyl then you must make this clear at the outset, then we can avoid charging another fixed price.

ii) we will always reserve the right without requiring your permission to make this colour available to other customers thereafter – thereby adding it as a standard colour for no additional fee to you, or to them.

When choosing a colour match select one of the last options: "Painted for me (TBC)" or "Bespoke - vinyl (TBC)". These selections may require manual adjustments, affecting the total price.

Please place the order (along with anything from our Accessories Shop) choosing Bank transfer as the payment option. Do not pay anything at this time. You are not committed to anything until your payment is made (later).

We can then add the additional values to your order. Next we will ask you to sign in to the web site to review your order, check things are correct, and click the Pay now button.

Can Extraglaze be fitted onto PVCu (already double glazed) windows?

If your PVCu windows are more than 15 years old then please consider: have you got the option to replace your windows with new ones? More modern secondary glazing, when fitted well, can be excellent. Your older PVCu windows are likely nowhere near as good, even if they are still in good condition, because glazing technology has improved.

However, see also sound proofing a little later in this FAQ answer. You can see examples of Extraglaze installed on PVCu windows (for sound proofing) in our Gallery.

Most PVCu frames, unless fitted within an older wooden frame, have handles that stick out, well into the room. Extraglaze will not fit directly over these PVCu window frames, because of the handles, and because you need a larger gap to achieve a good level of insulation. The correct way to fit Extraglaze is always to enclose the handles. Therefore you can install Extraglaze over PVCu windows with the addition of a simple sub frame, a bit further into the room, taking up your window sills. For this please order a Free Sample and Measuring Guide from our web site then discuss it with a local joiner or handyman. Consequently your secondary glazing aspirations might prove expensive.

Therefore, if your PVCu windows are not in good condition, quite simply we would recommend you invest your money in replacements.

To help you decide there is good information in our other FAQs too. For example: What depth of air gap is best on my windows?

In case sound proofing is important please see our article: How do I sound proof my windows?

ABOUT OUR PANELS

What are Extraglaze panels made from?

Extraglaze panels are made of 3mm thick* clear cast** acrylic (not glass). We only use genuine branded Crylux® (prior to August '23 we supplied Perspex®, then during a transition period a mix of both). Around the edges we apply magnetic tape with a white, industrial, tape adhesive. The magnets increase the overall thickness by another 5.2mm. The total nominal thickness is therefore 8.2mm. Furthermore we colour match the edges of every panel to your windows using a vinyl tape which you select from our standard range, or you can ask us for a bespoke colour (please call us to discuss), or for no additional cost we can prepare your panel edges for DIY painting. The tape (or paint) additionally masks the magnets. The best way to get familiar with this description is to order a Free Sample from our web site.

Acrylic, although it can be graded differently, is widely used in aviation for windows and helicopter cockpits, for car headlamps and in most spectacles. All of these items get a lot of wear over several years in constant service, so you can be reassured it is robust. It is not susceptible to UV damage, crazing or discolouration (imagine high altitude UV exposure on a long haul flight). When the sun passes through acrylic less than 7% of the energy is absorbed, compared to other plastic glazing materials that heat up and expand very rapidly.

Acrylic is clearer than glass and half the weight. And of course it does not have the fear factor of glass when handling.

Finally acrylic can crucially flex: in older properties it is very common for window frames to be a little distorted – therefore in combination with the magnetic edges our Crylux® acrylic panels can flex to the shape of your window frames and make a perfect seal.

Saverglaze panels are made from 3mm thick clear extruded acrylic.

We do not use 4mm thick acrylic because this would increase the weight of the panels, and put an unnecessary load on the magnets. The extra 1mm nominal thickness would not make a noteworthy, better choice of insulation. Very rarely we might use 2mm thick acrylic (for special installations), however, this material is more difficult to manufacture, so, while lighter duty, it is more expensive.

*the manufacturing process of casting acrylic means the thickness can vary. So some panels are a bit thicker, some are a bit thinner.

** Cast acrylic can be compared to extruded acrylic as follows:

- better chemical resistance

- comparable or better scratch resistance***

- reduced internal stresses, allowing it to perform better when being cut, and after cutting.

The Crylux® we use for Extraglaze panels is widely used in the cosmetics industry – please imagine the “crystal cabinets” used in department stores, typically for the perfume counters. These counters are almost constantly being polished and exposed momentarily to some cleaning agents or chemicals (like nail varnish & nail varnish removers), on a daily basis.

***there are different types of scratch tests.

Should I choose the premium Extraglaze, or the budget Saverglaze?

For a few years we abandoned Saverglaze, because we needed and successfully developed a better, more reliable product - which is now our Extraglaze product. However, with pressure to offer a budget option we brought Saverglaze back. We would suggest Saverglaze should be chosen only when budget comes first, where the situation does not require the very best (for example in a shed or workshop), or where the property only needs a temporary fix, for example if you plan to move out or do more extensive renovations (and then install Extraglaze) after one or two more winters. In our experience the adhesive used on Saverglaze magnets has a small, unpredictable failure rate - consequently it is not as reliable as Extraglaze, and is sold without any warranty whatsoever. The other aspects to consider with Saverglaze are highlighted in the comparison chart on our home page. Although we have a limited understanding of other brands of magnetic secondary glazing we believe they are prone to the same quality issues as Saverglaze. So if you want to invest well, and choose only the best magnetic secondary glazing then we recommend you choose only Extraglaze.

Is acrylic better than other glazing materials e.g. glass or PETg?

Acrylic is better than glass in many ways. It is significantly clearer. Most spectacles are made with acrylic. It is safer, as it can take a hit unlike glass. Acrylic is 17 times stronger than glass. It will certainly never be as dangerous as broken glass. It is also much lighter, at least half the weight of glass (plus Extraglaze has only magnets rather than a frame). For these last two reasons Extraglaze is safe and easy to lift away to open or to clean your windows. For secondary glazing purposes acrylic is also flexible enough to take on the shapes of old timber window frames, and numerous layers of paint, which are often far from perfectly flat. Trying to attach a glass panel using magnets in the same way will almost certainly fail, and indeed could be very dangerous!

When compared to PETg, a cheaper material used for modern impact resistant glazing, Extraglaze's choice acrylic is at least 5% clearer and does not need to be UV stabilised. PETg has a slight tint. PETg is also less scratch resistant than acrylic. Whereas acrylic can be polished, PETg can't.

Why do you use acrylic for Extraglaze panels?

Acrylic is an excellent choice for Extraglaze panels. Acrylic has been used in lots of glazing applications for many years, including most spectacles, counter tops (typically department stores), safety guards, motor cycle helmet visors, car headlamps, police vehicle protection, greenhouses and even aircraft cockpit hoods. It is much tougher than glass, does not soak up infra red and expand like other plastics when in the sunshine, is unaffected by UV rays, does not discolour and is optically very clear indeed.

Are the acrylic Extraglaze panels brittle?

No. Acrylic is known as an "engineering polymer" which means it is a premium material of choice for important components in all kinds of tough environments. We have first hand experience of dropping quite large panels (by accident of course!) - we worry more about the damage the panel might do than the damage to the panel itself!

Can Extraglaze panels be installed outside?

No. Acrylic expands and shrinks as the temperature changes, and therefore the panel will move (down, because of gravity). While a panel installed inside your home will stay close to room temperature, a panel left outside will likely experience constantly changing temperatures and extremes in the range -10 to 25º centigrade and beyond.

DIY INSTALLATION

How do I install Extraglaze secondary glazing?

An A4 printed Fitting Guide is supplied with your Extraglaze Panels. Following the guide is essential for a right-first-time installation. The Guide is very well illustrated and more comprehensive than a video. We believe it is easier to work with than a start - stop - rewind - repeat video.

We find most customers need help at the measuring stage, not at the installation stage. If you would like some help please contact us. We will happily look at photos, share a video conversation with you and discuss your windows, and from time to time explain a trick you can employ when something about your window presents a bit of a challenge.

Installation Basics

Extraglaze Secondary Glazing is applied on the inside of any window, never outside. Our Measuring Guide is fully illustrated and will answer a lot of your DIY questions very quickly. If you need to discuss your windows we are ready to help. We'll almost certainly request some photos - these should be taken indoors, without drapes or blinds, and when bright outside light does not wash out the detail. We'll want to see the windows as a whole, some details of the frame woodwork (from about a foot away) and any other details you think we should know about.

When looking at your windows all we need to know is that:

1 - there is a flat surface all the way around each window

2 - the flat surface is in good condition (good paintwork)

Is it best to avoid large panels?

The answer is a simple Yes. Each of the following explanations need not apply to your installation if you choose smaller panels whenever possible. Please do not hesitate to ask how we would do the work on any large window. We have over 15 years experience, installing thousands of panels and in many diverse situations.

The following explanations are cautions - neverthless we do sell and install large panels, with great success. In all honesty problems are brought to our attention very rarely. It's just that, when there is a problem, we take it very seriously and learn from it.

Here is what we have learned about large panels!

As a guide large panels are longer than 1.4m in any direction, or over 1.3 square metres in area (see also our FAQ answer about oversize panels).

Please also consider how "large" is subjective. For example even a medium size panel can be large if:

- installed in a busy or tight-for-space room

- installed overhead/high off the ground

- much longer one side than the other.

Large panels are naturally more difficult to install. We strongly recommend you do not install them alone: when fitting a large panel someone should control the panel position at the bottom, while the other person controls it at the top. While positioning it we also recommend you support the panel underneath so the weight is on a block or packer - so that it does not slip down when positioning it. This easily happens without you noticing it, until, despite extra careful handling, you find the magnets have stuck where you didn't want them.

Furthermore large panels are simply more difficult to handle, should you want to open a window, or just to get behind a panel, for example to deal with ladybirds or a spider in the gap. Such events will happen. Manhandling large panels, especially regularly, may risk damaging them, or wall and ceiling surfaces, ornaments and furniture, even curtains (panel corners can snag on these). Very large panels are floppy when being moved and may take you by surprise.

It's best to take large panels off your windows in the summer months, except perhaps on north facing windows.

The bigger the panel the more difficult it may be to store. If you plan to store them away during the summer you will need a suitably large space: while small panels may go behind a sofa or under a bed large panels may not.

Large panels suffer more than smaller panels from Thermal Expansion. Sunshine will cause them to move about on their magnets, as they heat up and expand, and again as they cool down and shrink back again. During these movements gravity will pull them down – remember of course that these are always going to be heavy panels. Therefore large panels must not be installed where the panel will get direct summer sunshine.

If you have shutters or thermal curtains over your windows then we would be particularly cautious about choosing large panels there (see also the next paragraph in this FAQ answer). Especially if they will be closed to block out the summer sun. The unventilated panels will simply bake in the sun. They may even suffer permanent damage caused by overheating. There are also out-of-season spells when the sun can be very strong, as late as October.

We strongly advise you do not fit large panels if they are likely to remain wet for many hours or stay in a very humid atmosphere*. For example a panel may be covered in condensation after taking a shower, then you do not ventilate the room properly. Condensation like this can also appear behind shutters or thermal lined curtains and the panels stay wet for long periods if the shutters or curtains are not opened in the morning/daily and dried.

* humidity will be high if you do any of the following without proper extraction...

- take long hot showers/bath/use a hot tub

- lots of steamy cooking

- dry your washing indoors

- exercise indoors

- steam iron many items

- live in or run a property with many occupants.

P&P costs may be very high, when packed into oversize parcels. This will depend on the courier we are using, which changes from time to time.

Flat surfaces absent?

In some situations one or more flat surfaces are missing. An example is shown in our video called "Watch an Overview..." (find this in our Gallery), and some other example appear on page 11 of the Measuring Guide. Our fitters are resourceful, and can usually add a very effective instant, white flat surface. Often there is a simple DIY fix, adding a small timber, or our PVCu right angle channel. Where there is no surface adjacent to a staff bead then it is not difficult to remove the staff bead and place a batten there, then refit the staff bead on top.

Handles or hardware sticking forward?

We recommend you order a Free Sample and hold it close to the window. You will see that the thickness of the two magnets on the sample will help, offsetting the window-side surface of the panel 5mm into the room.

Here are some options to bring the surface even further into the room, using items available in our Accessories Shop:

- adding an extra layer of our Extra High Bond Adhesive will add 1mm to the frame-side magnets (before you fit them)

- adding an extra layer of magnet will add 2.5mm (please ask us to do that for you when we make your panels. We will apply this to the panel-side magnets. An extra charge will apply: price on application)

- applying our flat PVCu channel to your frame surfaces with our Extra High Bond Adhesive will add 4mm

- applying custom timbers will add any extra depth you decide is required. This is likely very easy to do: for one of our fitters, or a joiner with a table saw (to tailor each timber here and there). When ordering timbers in our Accessories Shop, please make sure you specify the actual sizes you need.

To measure the required offset please place a suitable length of straight edge/batten across your window, so each end is resting on the existing perimeter surfaces, then position it so it touches the protrusion. It can help to rotate the batten (possibly requiring it to be longer than the window width) into the best touching position.

Sash windows - what to do about staff beads that stick proud?

On sash windows it is common for the staff beads to be fitted badly or they simply stick out further than the surface of the frame (please click to zoom the illustration). The "sandwich" of magnets on the back of the glazing panel are altogether just over 5mm thick - consequently the inner panel surface can bridge a bulge of up to 5mm. If your staff beads stick out more than this then you can probably refit them (correctly) which is generally a good thing to do, with a little repainting afterwards. Or you could replace them with a smaller staff bead.

For other, reasonably straight forward, DIY solutions to this problem please see the preceding answer (above), Handles or hardware sticking forward?

NOTE: when bulking out please remember the depth of the Centre Bridging Timber will need to be adjusted.

Window painting

If you are painting your windows in advance of Extraglaze Secondary Glazing it is very important to do this to a professional standard. This would include removal of loose paint, a good sanding down, cleaning with methylated spirits (use white spirit for oil based paints), and primer applied before undercoat or top coats.

My window frames have wood stain instead of paint. Will the magnets stick?

Some (not all) wood stains are intended to work outdoors and will repel rain water. This might be a problem: it could be formulated with a wax or a chemical that stops our magnets from sticking to it as it should. The best way to check whether this is a problem is to apply the pieces of your free sample to your window frames: wherever you think will test the adhesion best*, and in the same spot as a panel magnet would go in the future, then leave it 24 hours. The logic is as follows: when you remove the magnet the next day (perhaps forcibly) it should ideally remove the wood stain with it! Because that indicates it has stuck well. In which case you will be "good-to-go", and soon you can apply a panel over the patch in any case, so no harm is done.

*test the surface itself before you apply the magnet there: choose a spot where the paint is not likely to come away easily i.e. no flakes/repairs/free from sub-surface lumps etc.

If the magnet comes away easily there will be a solution. It might be necessary to scratch off the wood stain then apply a special primer, or reapply with a modern wood stain (probably for internal use rather than external): one that passes this adhesion test. Alternatively please discuss your situation with us for advice.

How do I order a SHAPED panel?

Shaped panels will be priced higher than standard rectangular panels.

Before you place your order we recommend you send photos of your windows, with dimensions, so we can advise you.

Tight curves: A radius under 200mm will require extra labour time.

Example

Imagine you have 4 arched panels:

1 @ arched panel “A”

3 @ arched panel “B” (all identical)

These will be priced as follows:

Price for panel A as if a rectangle, plus 1 @ “unique design” supplement

Price for panel B as if a rectangle, plus 1 @ “unique design” supplement, plus 2 @ “duplicate design” supplements.

Please also read the next FAQ answered immediately below here.

How do I send measurements for a special shaped panel?

Please view our Templating Guide. We will insist you follow our prescribed methods only. You must take full responsibility – if the panel we make does not fit then you will have to pay us again to make another one, unless we got it wrong. We reserve the right to reject templates and descriptions, and when we think something is amiss or risky, because we will only make a panel if we think we can get it right first time: we will not risk your money!

Circles

Firstly, please get to grips with our Measuring Guide and apply what you learn there. Next, please check whether or not your porthole is a true circle. If YES then tell us the diameter including magnets around the perimeter. If NO then you will need to follow our Template method (see next). Note: panels below 450mm diameter are difficult to make, therefore any little circular panel(s) might prove surprisingly expensive.

Template method: for triangles, arches and other curvy shapes

Please email us to request a sheet of polythene. As described in the Templating Guide tell us the size of the template you require: it is probably best to specify it 50mm larger in both directions: width and height. When templating be super careful so you do not fall forward onto the window glass.

Special note for Step 1 - you will find tracing a whole lot easier with a short straight edged stick (say 100mm long) and a long stick (strong and wide enough to rest either side of your arch here and there). Rest the short stick on the inner rim edge, then draw short lines by running the biro against it. Eventually you will have the shape, by joining those "dots". Use the long stick as rest for your wrist.

Special note for Step 2 - if you have more than enough flat space around your arch for the magnets to fit there (for 12.5mm or 20mm wide magnets respecitively) then this step can be ignored.

Laser & sketch method: for out-of-square rectangles

We recommend this method only if you have a self-levelling laser (separate plumb and level lines).

DXF for a laser cut panel

For some shapes this method is very appropriate, especially if there are lots of duplicates. For large panels this is very expensive. We do not have a laser here, so this work will be contracted out. Please send us a DXF and a PDF technical drawing of the final shape, marked up fully with dimensions and radii. Dimensions must include magnets: we will not adjust your DXF in any way. Prices are available on application when we see your PDFs.

Can I paint the panels with my own colour ?

Yes (for DIY installed panels).

Please order a Free Sample in advance and become familiar with it. Use this to practice removing the masked edges correctly (see below).

When ordering your panels, if you choose the No colour applied DIY option then:

- the panel edges will be masked, making it very easy to paint around the panel

- the panel edges and foundation magnets will be supplied without vinyl

- the panel magnets (the ones stuck fast to the back of panels) will have a separation barrier layer applied, so that these magnets are less likely to fuse with your paint (otherwise the panel will get stuck, a consequence of being pressed against the paint for long periods).

IMPORTANT TIPS FOR PAINTING

- Never use Vuplex® on a panel until all your painting is complete

- remove the masking tape carefully as follows. Start at the very edge, by a corner. As you peel, an inner part of the masking tape should remain in place, with a clean edge: this runs around the panel a little way from the edge. The freshly revealed acrylic surface is now ready for painting. Try to keep it free of dust and fingerprints

- you should experiment: order a Free sample and paint it, using the tips shown here. Check your choice of primer grips well

- we recommend surfaces are sanded lightly even for the primer coat (180 grit or finer)

- the first coat of paint should be a primer. Use a new primer, not an old one. Acrylic primer should work fine

- the panel & magnets and the paint must be above 15 degrees centigrade (don't paint on a cold day outside, and don't use materials brought inside that are still cold)

- apply one coat of primer and two coats of paint

- follow each paint's Directions for use, especially drying times

- AFTER all the paint is dry we recommend you rub a little Vuplex® on the panel magnets (the magnets on the back of your panel). This will make these magnets completely non-stick, so the painted ones (i.e. the foundation magnets) can't gradually stick to them. Do this by wrapping a cloth around your finger, then squirting a little Vuplex® on to make it wet, then wiping this along the magnets. After a minute or two wipe dry.

Can I order a very large (oversize) panel?

Generally we do not make panels over 2.15 square metres. We may make an exception and this will be priced separately. We will apply additional magnets *(i.e. wider magnets), to take the additional weight, consequently you must add more to your panel dimensions, and have wider surfaces available for the magnets to adhere to.

Please consider the following practical issues before requesting a oversize panel...

Large panels are naturally more difficult to install. Furthermore they are simply difficult to handle, should you want to get to the window, for example to deal with ladybirds or a spider in the gap. Such events will happen.

Large panels are best taken off your windows in the summer months, except perhaps on North facing windows. Therefore you will need a suitable space in which to store your oversize panels.

Manhandling oversize panels, especially regularly, may risk damaging them, or wall surfaces and furniture.

Oversize panels suffer more than smaller panels from Thermal Expansion. Sunshine will cause them to move about on their magnets, as they heat up and expand, and again as they cool down and shrink back again. During these movements gravity will pull them down - and these are always going to be heavy panels. Therefore oversize panels must not be installed where the panel will get direct sunshine.

Oversize panels must never be installed where shutters or curtains will be closed over them to block out the summer sun. The unventilated panels will simply bake in the sun. They may even suffer permanent damage caused by overheating.

P&P costs may be very high, for being packed into oversize parcels.

After any oversize panel has been delivered safely we will not provide any kind of warranty.

MAINTENANCE

How do I keep Extraglaze clean?

Extraglaze must only be cleaned with an new/uncontaminated microfibre cloth. Please never use any other type of cloth, and never use a paper tissue (tissues usually contain tiny amounts of a mineral powder which will scratch just about anything!). Microfibre cloths are very cheap and very easy to find in any supermarket or hardware store. A very clean soft cotton cloth might sometimes be acceptable, but is nowhere near as effective as a microfibre cloth. Whereas a microfibre cloth will literally grasp dust particles as soon as it comes in contact, a cotton cloth will just sweep some of the dust around. Do not use a "used" microfibre cloth, because this may have dirt caught up in its fibres, which will scratch your panels.

What cleaning agents shall I use on Extraglaze?

Extraglaze panels are best cleaned with VuPlex® anti-static cleaning fluid (this was specially developed for the aviation industry, for cleaning cockpit windows). A tiny amount will clean and polish an Extraglaze panel in a few seconds with minimal effort (always using only a new microfibre cloth). You can buy VuPlex® in our online shop. If you employ our "Fitted by Us" service then we will supply you a can of this at the end of the project. You can also use very dilute solution of soapy warm water, though without both the anti-static and the polishing effects.

My panels have arrived scratched. What should I do?

We inspect every panel we send out - thousands every year. We would never knowingly send a scratched panel to a customer. It is very likely the damage you see on a newly arrived panel has been quality checked already and will prove to be a false alarm. But once or twice a year one slips through the net.

All our panels are covered with a protective film. While this film is not impenetrable, it is surprisingly effective at protecting your panels. In fact it is common for the protective coating to be scuffed, scratched or even ripped open a little here or there. This suggests we have spent a lot of additional time inspecting every such panel to see if any damage has actually reached the panel itself. We usually catch any damage at this stage.

It is therefore very likely your panel is not damaged. In some cases the adhesive that keeps the protective film on the panel is smudged, and it just looks like a scratch. A rub with a clean finger tip will quickly show if this is the case.

How do I assess genuine panel damage?

On a very rare occasion genuine damage is found on newly arrived panels. If you discover a scratch we will be equally disappointed.

In most cases the “damage” is nothing more than a smudge, easily rubbed off with a clean finger tip.

With the protective film removed please take a very careful look at the damage. This should pay off all round. Put very simply this eliminates the down sides of a replacement, for example with further delays, and of course the inconvenience of getting your panel ready for collection, then the additional “waiting-in” for the replacement on the day of its arrival.

- Transit damage: This must be reported as per our delivery notifications, within 24 hours of arrival. Otherwise we have no recourse to the courier to make a claim on their insurance. It is essential you report this kind of damage inside this timescale.

- Severe scratches: Can you easily feel the scratch with your finger nail? If yes, then our quality inspection process genuinely failed - that kind of scratch is definitely not acceptable. We will replace the panel.

- Light scratches: with a little care and attention these can be polished out quite quickly.

How do I polish out a scratch?

Most scratches will rub out and disappear completely, and quickly, with a bit of scratch remover, "Brasso™" or "T-cut®" on a clean microfibre cloth. If you don't have these to hand please contact us so we can post these items to you.

Please be reassured this will do the trick.

Please read through the following instructions before starting. We hope the emphases help.

- Put a small piece of masking tape on the back side of the panel behind the scratch. Otherwise, as you apply a rubbing paste (see next step) you will lose sight of where to rub!

- For deeper scratches start with scratch remover paste. For lighter scratches put a bit of "T-cut®" or "Brasso™" on a clean cloth, give that area a rub using side to side and maybe some circular action now and then. Only use a new Microfibre or cotton cloth. Try to avoid polishing a larger than necessary area. Do not use a paper tissue - it will scratch the panel. Note: it can take up to 10 minutes of rubbing. It should disappear, or certainly be reduced. It might only take a couple of minutes. After 10 minutes it's not worth persevering: you have probably achieved all you can at that point.

- Wipe the panel clean using a clean part of the same cloth. A bit of methylated spirits or rubbing alcohol might help as a last wipe.

- If you have bought some Vuplex® plastic polish (from our Accessories Shop) then finish off with this. Simply spray and buff until this disappears using another clean part of your cloth.

My panel magnets don't grip ...OR... they don't align like they used to

This is not a common problem, but when it does arise there is a fix.

Please note: our magnets do not lose their magnetism. You can test this with a modern coin: try a one pence or a two pence coin. The coin will stick to the magnet. The problem will be misalignment.

The problem may be caused by incorrect installation (please see our note* below the numbered list), which can be corrected by refitting, but there might be another, much simpler reason. Before you do anything please consider the list of solutions below. It may be necessary to buy some extra FRAME SIDE ONLY magnets to remedy the problem (from our Accessories Shop).

Starting with the easiest potential fixes:

- Simply taking the panel off and putting it back on sometimes does the trick.

- When several of your panels are identical/near-as-dammit then it is quite possible they have been taken off and put back on another window/the wrong side (or even upside down - see next). You might have lost track of the original location (e.g. which is left, which is right). Please iterate until you get the best matching location for each panel.

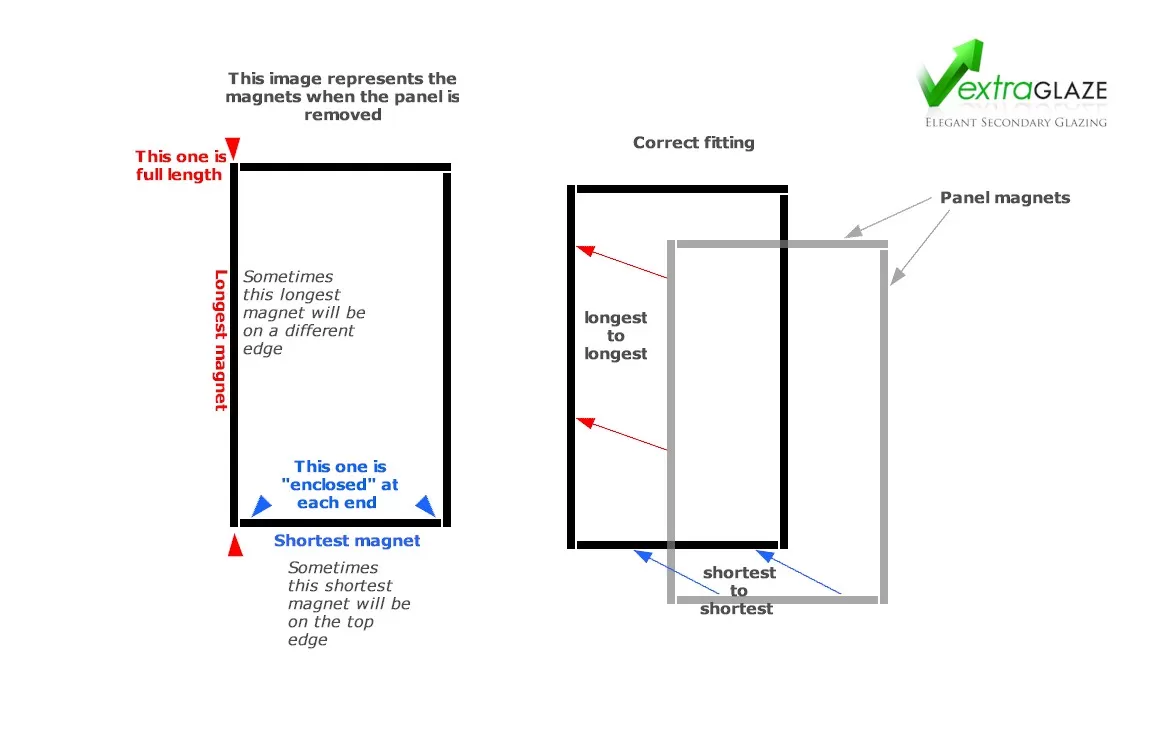

- Making sure the 'magnet pattern' is a match might also correct it. Do a basic check to ensure it is not fitted upside down (see the image below).

- If a panel has been exposed to a lot of...

- direct summer sunshine then it is at risk of overheating, and this may affect your panel negatively, as described here. As indicated in our Fitting Instructions please do not neglect to protect your panels from this risk. The plastic panel will expand when hot, then it will shrink again when the temperature drops (overnight). This causes the panel to move: nudging down because of gravity (see also item 1 above). If this is allowed to happen many times there is a risk the panel will change size permanently by a few millimetres (i.e. stretch, depending on its size and weight), enough to cause the magnets to misalign.

- water/condensation/very high humidity then this indicates a severe problem that must be solved if it is not to affect the panel again. Wetness or very high humidity over a long period will cause the panel to temporarily grow one or more millimetres and possibly start to bend a little, putting pressure on the magnets to keep it in place. Basically some moisture has been absorbed into the panel, and it has expanded a bit, like a sponge does when it soaks up water. The moisture needs to get out. When the panel is dried the panel will go back to its original size, although it may take a day or two (ventilation or with the heating on, potentially also with air conditioning) for the moisture to escape from within the acrylic. You will need to take steps to avoid the same thing happening again i.e. ventilate the room better in future or wipe/use a proper window vaccum daily so the panel stays dry. Water absorption is not harmful in any way, but it does change the dimensions of the panel until it is dried again. Please rest assured, the acrylic is the same material used on car headlamps for example, which last many years in all weathers.

When magnets are fitted misaligned it is necessary to reset the magnets. The simplest way is to remove one (or more) magnets on the frame and replace it with a new one, so it is on the window in the new position, and now matching the position of the panel magnet perfectly. Replacement FRAME SIDE ONLY magnets can be bought online from our Accessories Shop. Taking an old magnet off will likely damage the paint on your window, so please repair this/repaint then follow the Fitting Guide again.

To review this you can access the Fitting Guide online by signing in to our web site and finding the additional Welcome back menu provided there.

The most common errors are:

- the frame-side magnets were not checked for alignment on the back of the panel before fitting it to the window. Please see Step 3 of your Fitting Guide.

- when the panel was presented to the window for fitting the magnet adhesive started to grip at one or more corners, but before the remaining adhesive took grip the panel moved slightly, causing some misalignment. Please see Step 5 of your Fitting Guide.

- when the panel was presented to the window for fitting the magnets were not pressed firmly onto the window or later they were not rolled properly: as a result the adhesive was not pressed on to the frame sufficiently well. This will allow one or more magnets to dangle slightly then later grip the frame out of alignment with the panel. For Casement windows please see Steps 5 and 6 of your Fitting Guide. For Sash windows please see Steps 5 and 8 of your Fitting Guide.

- the surface of the frame has silicone or a waxy surface. This must be physically removed/scratched back, etc. Some external grade paints might contain a type of wax in the formulation, which we have witnessed first hand can get even waxier as the paint ages (in our case after about 48 hours).

ABOUT OUR MAGNETS

What colour are the magnets?

The magnets supplied on Extraglaze panels have a coloured top surface i.e. all the major surfaces you see when the panels are removed. Several colours are available when you place your order. Why not request a free sample? The obtuse edges (on the thickness) however (about 1.5mm) are dark brown, which is rarely of consequence, and are often unseen. The selected colour will be applied at the factory.

PLEASE NOTE: Alternatively, if you want the magnets painted (and indeed the panels) please discuss your requirements with us. For the panel edges we can certainly make this much easier for you to do, or we can do the painting for you. For more than a few panels we recommend we do the painting for you at the factory (this is an extra chargeable service).

What are “foundation magnets” ?

The “foundation magnets” are those that remain on the frame even after the panels are taken away. The mating complement of these are the panel magnets: these are the magnets permanently attached to our panels around the panel perimeters.

NARROWBOATS

Does secondary glazing start a dampness problem in other parts of the boat?

We sent this question to all the customers who have our product installed on their boats. Here are the replies we received, without our editing:

SB: reported after 5 years

no I have not had the problem you mentioned at all. No damp smell or dampness. Still a pleasure not waking up to condensation on windows. Also the extra insulation is another benefit.

LB: reported a little after 2 years

I haven't experienced any damp problems elsewhere. I am very happy with my panels

RB: reported after nearly 3 years

I found that condensation was virtually eliminated in the boat, but it depends on good ventilation as well. And a solid fuel heater also helps the situation.

SP: reported after nearly 2 years

Happy to respond. Condensation on narrowboats is a direct result of warm moist air inside (due to human habitation/breathing etc as well as heating) coming into contact with the cooler aluminium framed single glazed windows. Extraglaze immediately stopped this on the windows and we have not noticed an increase in condensation elsewhere. This will always occur in boats to some degree especially in areas of poor ventilation. Condensation on below-waterline panels [i.e. hull sides] will never disappear completely - it just has to be managed with better insulation and ventilation where possible and dehumidifier products during the winter.

To make an enquiry use the Contact Us page or email using